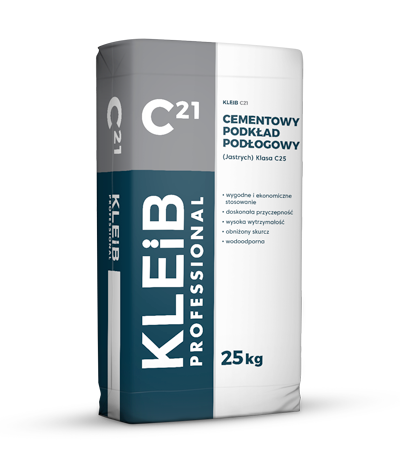

CEMENT SUBFLOOR

Kleib C21 is a cement mortar for making subfloors and screeds with the layer thickness of 10-80 mm to be applied inside buildings upon all types of mineral substrates for final finishing cladding such as: tiles of various types of materials, PVC flooring, carpeting, panels, boards, etc. It can be used for making cement floors (screeds) in less trafficked areas, such as basements, garages, utility rooms. Due to its properties it is suitable for use as a floating floor layer on the damp proofing or thermal insulation with minimum thickness of 40 mm (in the case of underfloor heating the minimum layer thickness must be 60 mm). It can also be used for local patching of surfaces, filling gaps and cavities in the floor surface with 10-80 mm thick layers.

- convenient and economical in use

- excellent adhesion

- high durability

- reduced shrinkage

- waterproof

25 kg

54

Approx. 2 kg of mass are used per 1m², with the thickness of 1.0 mm

CALCULATE CONSUMPTIONKleib C21 is a cement mortar for making subfloors and screeds with the layer thickness of 10-80 mm to be applied inside buildings upon all types of mineral substrates for final finishing cladding such as: tiles of various types of materials, PVC flooring, carpeting, panels, boards, etc. It can be used for making cement floors (screeds) in less trafficked areas, such as basements, garages, utility rooms. Due to its properties it is suitable for use as a floating floor layer on the damp proofing or thermal insulation with minimum thickness of 40 mm (in the case of underfloor heating the minimum layer thickness must be 60 mm). It can also be used for local patching of surfaces, filling gaps and cavities in the floor surface with 10-80 mm thick layers.

The substrate should be stable, structurally sound and clean, i.e. free from impurities that could impair the adhesion of the mortar, such as dust, bitumen, grease, oil or emulsion paint residues. Excessively absorbent surfaces should be primed with suitable primers before performing any work.

The mortar is prepared by pouring the entire contents of the bag into a container with a measured amount of water and mixing until a smooth, lump-free uniform consistency is obtained. This is best done using a concrete mixer or an electric drill with a mixer attachment in case of minor works. The mortar is ready to use after 5 minutes and after remixing. Prepared mortar is to be used within approx. 4 hours.

Apply the Kleib C21 mortar with a trowel or plasterer’s float pressing firmly and rubbing the mortar into the substrate. Larger cavities should be filled in layers of up to 80 mm beforehand. Leave each such layer to harden for 2-3 days. The ready subfloor or screed should be protected from drying out too quickly for the first 2 days, e.g. by sprinkling with water every few hours and covering with foil. Use the mortar at the temperatures from +5°C to +30°C.

Approximately 2 kg of mass are used per 1m², with the thickness of 1.0 mm.

The mortar must be transported and stored in tightly sealed bags, in dry conditions (preferably on pallets). Protect from dampness. Shelf life in conditions that comply with the specified requirements is up to 12 months from the production date on the packaging.